101024 Structural Engineering Seminar

Seminar Program Speaker Bios Exhibitor Layout

The 2024 Structural Engineering Seminar will be held on October 10, 2024, at the MDC Operations Facility & Training Center in Hartford, CT. Eight (8) New York State PDHs will be offered at this event. This seminar is sponsored by the CT Chapter of the ASCE Structural Engineering Institute.

Thank you to our sponsors!

This seminar will offer the following presentations:

A Case Study of Ultra-High Performance Concrete Invert Linings for the Rehabilitation of Corrugated Metal Pipe Culverts

Brian Lassy, EIT, of the University of Connecticut

Culverts are an essential infrastructure for hydraulic transmissibility for storm water drainage, natural waterways, and sewage. However, nearly 45% of culverts in the United States are rated in in Fair or Poor condition. Replacement is a costly endeavor requiring ground excavation, water redirection, and closures of traffic overhead. Corrugated metal pipe (CMP) culverts specifically face a problem of corrosion in the lowest portion of the culvert, otherwise known as the invert. Restoration and rehabilitation of culverts typically involves insertion of a smaller diameter pipe through the full length of the culvert, then application of high flow grout to fill in the area between the lining and the existing culvert. While this is an effective method of rehabilitation, it can pose issues for the hydrology of the waterway by increasing fluid velocity, changing the surface condition, and increasing the water table. For this reason, the Connecticut Department of Transportation and the University of Connecticut have tested a new method for low-profile invert linings using ultra-high performance concrete (UHPC). Due to the durability and strength of UHPC, a significantly thinning layer can be applied to the invert and not only restore structural capacity but prevent further corrosion at the base of the culvert. An existing culvert in Connecticut was identified for a pilot implementation for this repair method. Prior to field implementation, several mockup tests were conducted to prove the constructability of a UHPC invert lining. The methods and results of the small-scale and full-scale mockups are presented here, including tests with UHPC shotcrete, a thixotropic UHPC mix, and two methods for top-forming UHPC for the invert lining. Lessons learned for the pilot implementation, areas of further research, and recommendations for field implementation are discussed. This project aims to test new applications for UHPC and will provide a greater understanding of the challenges of UHPC constructability and methods to overcome them.

FHWA’s Resources and Solutions for Bridge and Tunnel Security Engineering

Vincent P. Chiarito, P.E., F.SEI, M.ASCE, of the Federal Highway Administration, Office of Infrastructure

The Federal Highway Administration (FHWA) is committed to assessing potential risks to U.S. highways, roadways, tunnels, bridges, and other infrastructure and providing solutions to protect these assets and the public. FHWA’s focus includes providing effective solutions for protecting critical highway infrastructure and ways to reduce risk from intentional or related multi-threats. The Blue Ribbon Panel Report, (2003) presented a strategic vision and recommended actions for FHWA to take regarding terrorist threats and security concerns as a result of the September 11, 2001 attacks One key recommendation was the process that is a cornerstone of a methodology called “Risk Management for Terrorist Threats” to Bridges and Tunnels. The “Risk Management for Terrorist Threats” process evolved into a more generic title of a “Threat Vulnerability Risk Assessment”, (TVRA). Several major bridge projects used the TVRA process, and the results helped develop security protection plans that detailed strategies to mitigate human-made threats. FHWA cites noteworthy industry TVRA practices for bridges and tunnels that follow a physical security design philosophy: deny, deter, delay, and defend. A TVRA enables bridge owners to identify security vulnerabilities, assess risks, and make appropriate decisions about risk acceptance and noting possible mitigating actions. The risk management decisions may include selecting mitigation measures. Since 2003, FHWA has led efforts to fulfill the vision and strategies set by the Blue Ribbon Panel. This presentation will summarize what FHWA has accomplished through collaboration with other agencies and stakeholders since 2003 and identify ongoing efforts. The future efforts are designed to support stakeholders with enhanced security tools and solutions that maintain or increase resiliency and meet safety goals for bridges and tunnels.

Vessel Collision Evaluations for Major Bridges

Matthew Lengyel, P.E., S.E., PMP, CBI, of GM2, Inc.

Vessel impacts to major bridges has increased significantly over the past 60 years, with 36 major bridge collapses being recorded worldwide between 1960 and 2024. Nineteen of those collapses have occurred in the United States, including the most recent Key Bridge Collapse in Baltimore, Maryland.

The collapse of the Sunshine Skyway Bridge in Tampa, Florida in 1980 spurred efforts to provide Vessel Impact design guidance in the AASHTO code in the United States. The first Vessel Collision Design of Highway Bridges Guide Specification was published in 1991. The detailed procedure in this code is a probabilistic analysis method that differs substantially from other parts of the AASHTO code, which introduces challenges for engineers conducting a vessel impact evaluation that could produce multiple acceptable solutions.

This presentation will first give a general overview of AASHTO Method II, introducing all of the variables that may need to be considered on major bridge projects. Each variable will be discussed in detail with a focus on current best practices, especially where the engineer’s judgement is needed to determine vessel data, characteristics, and project specific variables. The different possible solutions that can be developed will be discussed, and how different engineering decisions made during an evaluation can impact possible design solutions. Case studies of major bridge vessel collision evaluations will be presented, including the controlled factors involved and the necessary decisions made by the owners and engineers in selecting each of the solutions.

Design Development & Construction Challenges of the Onondaga County Canalways Trail Extension Project

Alexander S. Kerr, P.E., PTOE and Kimberly Fletcher, P.E., of Barton & Loguidice

The proposed presentation will discuss the engineering and coordination challenges designers overcame throughout the design and construction of the most recent extension of the Canalways Trail (PIN 3756.29). The project, entitled the “Onondaga County Canalways Trail Extension Project Phase 2 – Segment 3”, was located along the southern shores of Onondaga Lake in Syracuse, New York. This project not only continued the state-wide Canalways Trail network but also expanded Onondaga County’s Loop the Lake Trail. The vision for the Loop the Lake Trail dates back to the 1970’s and aims to provide a multi-use trail which completely encompasses Onondaga Lake. Furthermore, this project is now included within the 750 mile Empire State Trail network which fully opened on December 31, 2020 alongside completion of the Canalways Trail Extension Project.

The project consisted of creating a multi-use recreation trail which would connect the previous segments of the Canalways trail to the Greater Syracuse Area. In order to do so, the trail extension needed to traverse several active freight lines (CSXT & NYSW) and a series of environmentally sensitive lands. A Total length of 2850 feet of new trail was constructed as a result of this project. Being located next to both Onondaga Lake, a former metal scrap yard, and the Syracuse Metropolitan Wastewater Treatment Plant the project faced a number of constraints and unique coordination efforts with stakeholders such as CSXT, Honeywell, OCIDA, and OCDWEP. The project was fast tracked to meet the Governor’s initiative to complete the “Empire Trail” by December, 31, 2020. To further complicate the project to meet the deadline on an 8 months construction duration the construction was completed in

the midst of the COVID-19 pandemic.

This presentation will serve to provide an overview of the more unique structural issues faced

throughout the project’s lifecycle and inform listeners of the engineering solutions developed. Major highlights include:

1. Substructure

- Due to the poor and contaminated soils near the lake, a thorough geotechnical analysis was conducted, leading to the design of piles that are up to 250 feet deep. Additionally, the piles had to be chemically treated to a specific depth in order to prevent corrosion from the contaminated soils. A total of 15,400 feet of steel H-piles were installed

- GRS retaining walls were used to transition from at-grade trail to the elevated bridge spans

- The GRS walls had to be designed/supported by lightweight fill such that zero settlement would occur over time

- Zero settlement needed to be achieved due to the presence of a 36” and 30” sanitary force main which brings a substantial amount of sanitary flows from the City of Syracuse to the Syracuse Metropolitan treatment plant

2. Superstructure

- The highlight of the bridge is the tied arch main span with crosses over CSXT

- There were several design challenges that needed to be met to satisfy CSXT’s design manual requirements. Namely being a minimum 23’ above the active rail tracks

- The main span had to be erected in two pieces simultaneous by cranes on either side of the railroad tracks during construction which was a tremendous coordination effort with CSXT flaggers

- The piers were designed with aesthetics in mind and featured curvature to them (as opposed to traditional orthogonal piers)

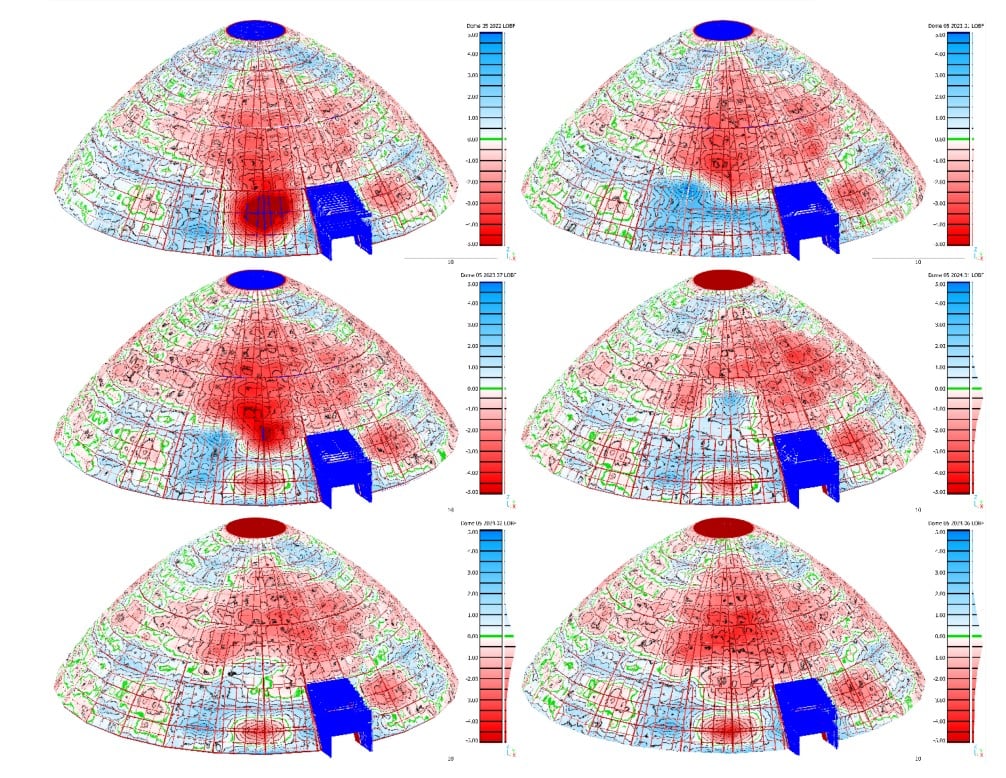

A Snapshot in Time (Digital Twins)

Chase Gallik, EIT, and Hannah Rakowski, P.E., of Wiss, Janney, Elstner Associates

LiDAR technology, a cornerstone of Digital Twin applications, offers exciting possibilities for structural engineering. In this presentation, we’ll explore various LiDAR capture methodologies, from SLAM to traditional terrestrial scanning. Case studies will illustrate its versatility, including floor-level analysis, as-built documentation, and even Finite Element Analysis (FEA) model creation. But beyond the present, LiDAR enables us to compare structures across time. By preserving highly accurate measurements digitally, we can revisit sites later, assessing changes in appearance and critical engineering factors like deflections, section loss, and rotation of structural members. Repeating scans under the same load cases at different points in time can help detect weaknesses forming within the structure. Additionally, repeating the scans over shorter periods of time under different load cases can help engineers understand how a structure is behaving in its current state. As we peer into the future, with compute and data storage costs approaching zero, and advances in AI and machine intelligence promising even more exciting applications, LiDAR’s precision, speed, and accuracy empower us to capture detailed 3D representations of our physical world, both for us and for generations to come.

R. Buckminster Fuller (1895-1983)’s Engineering Challenge

Chad T. Morrison, P.E., F.ASCE, of the Berlin Steel Construction Company

Bucky’s Engineering Challenge – Best known for writing “Operating Manual for Spaceship Earth” and design of geodesic domes, Buckminster Fuller (1895-1983) issued a challenge to engineers to lead efforts for improved sustainability, education, and quality of life. A reintroduction of Bucky will focus on his many contributions to the engineering profession. Concepts emphasized will be how to promote systems change and what it means to be a comprehensive anticipatory design scientist. The undertaking for engineers is to better understand their position as specialists so they may become comfortable in scaling their abilities and thinking in a way that best suites the problem at hand. What is the benefit for engineers in studying Fuller’s body of work? What makes it unique? A current snapshot of Bucky’s influence on people, artifacts, and ideas will be shared. It is up to new engineers to better understand the nature of structure. This can be achieved by embracing our role as innovators. Also, by collaborating in ways that Fuller envisioned using the technology he foresaw. The future can be bright with the vision that there is enough for all. We can do more with less in terms of resources and energy. Automation frees the engineer to think of bolder ways to tackle our greatest local and global issues. It encourages us to step up as leaders and elevates our profession within society. In doing so we demonstrate that engineers have no shortage of “know-how.” Overall, Bucky’s work is an effort to expose generalized principles so that they can be fashioned into a solution. Try first and explain later – learn to trust your experience and develop judgment. Design is an iterative process and often we cannot explain work until it is complete.

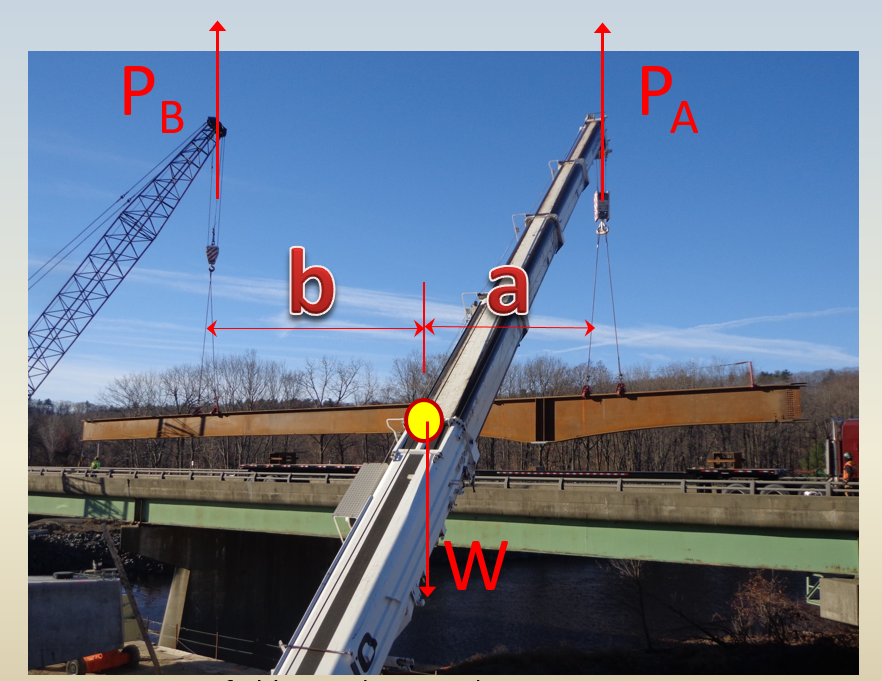

The Six Most Important Issues for a Crane Lift Plan

Vincent A. Siefert P.E., M.ASCE. Past Chair ASCE Construction Institute Temporary Works Committee and Steven L. Porter EIT, M.ASCE, Siefert Associates, LLC

Engineered Lift Plans are an integral part of a safe and successful construction project. Cranes are the most common type of lifting equipment onsite and are constantly evolving. Larger and more innovative mobile cranes are being manufactured utilizing the latest in microchip technology. To perform safe and efficient lifting operations a thorough knowledge of crane capabilities and their inherent hazards must be understood. This knowledge is seldom taught in the academic world and can generally only be gained by experience.

This presentation describes the best practices for developing an engineered lift plan utilizing locally available hydraulic and crawler type cranes. Engineered lift plans consist of working drawings accompanied by supporting engineering calculations along with appropriate appendix data that demonstrate how the lift will be performed from start to finish. Preparation of these plans by a registered professional engineer are generally a contractual requirement for most infrastructure projects and many industrial and commercial projects. The plans are submitted for review and approval to the owner and/or their authorized representative for concurrence that the lifting operation can be safely carried out without risk to the public nor damage to property. This presentation is based on the practical experience gained through several decades of preparing engineered lift plans for contractors and also from self-performing and witnessing many successful demolition and erection operations in tight urban environments. The following list summarizes the six most important issues that will be discussed with examples and sharing of important industry “rules of thumb”:

1. Verification of load and center of gravity (the MOST important issue)

2. Assuring adequate crane capacity (including tandem lifts)

3. Consideration for site constraints (and their effects on radius and boom length)

4. Proper methods to support crane outriggers and crawlers (and geotechnical engineering considerations)

5. Determining stability of the lifted load (steel plate girders and rebar cages as examples)

6. Importance of a detailed written procedure

This talk will be useful for contractors, engineers and owners who all play an important part in the engineered lift plan preparation, review and approval process. All parties will benefit from enhanced knowledge that will result in improved safety during lifting operations.

Beyond a Bridge: Empowering Communities

S.B. Sanjeev Mohan, P.E., Stantec

The Engineers in Action Bridge Program (EIA) is a unique initiative that empowers student engineers and addresses critical infrastructure needs in underserved communities worldwide. By leveraging student expertise and collaboration with industry professionals, EIA has successfully designed and constructed over 110 footbridges in 12 countries.

As a Bridge Corp for the program, Sanjeev Mohan has been involved with 3 bridges and has played the role of mentoring students through design processes, report writing, plan preparation and has been the Field Engineer in Charge for 2 projects – one in Bolivia and the second in Eswatini (Africa). To provide a personal touch on how engineers play a vital role in community empowerment, the presentation will include a photographic story line walking the audience through the bridge builds and cover various challenges of working in underserved communities. The presentation will cover examples of:

- Technical Oversight: Reviewing design reports, providing feedback to student engineers, and ensuring adherence to engineering standards.

- On-Site Leadership: Guiding the construction process, ensuring quality control, and mentoring students on the field.

- Community Engagement: Collaborating with local stakeholders to understand their needs and address project challenges.

This presentation will delve into the transformative impact beyond engineering - on communities and its educational benefits for students. We will discuss:

- Community Development: How footbridges improve accessibility and safety, fostering economic growth and social empowerment.

- Student Learning: The valuable hands-on experience students gain in design, analysis, construction, and project management.

- Sustainable Practices: The program's commitment to environmentally responsible solutions.

By sharing insights from specific projects, he aims to showcase the effectiveness in providing sustainable infrastructure solutions and empowering communities.

Early Registration Levels Until September 13, 2024 / Regular Registration Levels:

ASCE Member (includes NYS PDHs) - $250 / $275

Non-ASCE Member (Includes NYS PDHs) - $300 / $325

Government & Educational Institution Employee & Retiree (Includes NYS PDHs) - $100 / $125

Younger Members (Under 35 & Includes NYS PDHs) - $175 / $200

Full-Time Student (Student ID Required at Registration - No NYS PDHs) - $30 / $50

Early Registration Levels Until September 13, 2024 / Regular Registration Levels:

Morning Break Sponsorship (2 1 Available) - $500 / $700

This sponsorship level includes 1 exhibit table, your company logo on table placards during the morning break & networking break, podium mentions, and 1 attendee registration.

Afternoon Break Sponsor (2 1 Available) - $500 / $700

This sponsorship level includes 1 exhibit table, your company logo on table placards during the afternoon break & networking break, podium mentions, and 1 attendee registration.

Program Sponsor (2 Available) - $1,000 / $1,200 SOLD OUT

This sponsorship level includes 1 exhibit table, your company logo on the program cover and on table placards during all breaks including the lunch break, podium mentions, and 2 attendee registrations.

Registration Sponsor (1 Available) - $400 SOLD OUT

This sponsorship level includes the opportunity to place a banner and promotional materials at the registration table, your company logo on table placards during the morning and networking breaks, podium mentions, and 1 attendee registration. Note: This level does not include an exhibit table.

Profits from CSCE continuing educational activities fund the CSCE scholarships.